Spring manufacturing requires an artistic touch. Manufacturers use many different techniques to create symmetrical springs that retain their ability to absorb shocks and store energy while keeping their shape over long periods of time. At Southern Spring and Stamping, we use coiling, winding, or bending processes to create high-quality springs through both manual and automated processes.

We’re experts in the compression spring manufacturing process. We specialize in a wide range of spring-manufacturing techniques that benefit a variety of applications. Here, we describe the basic spring manufacturing process to give an idea of how versatile our springs can be.

How We Build Springs

We build springs following three basic steps:

Coiling

First, we feed the wire through a straightening process. The straighter the wire as it enters the coiler, the better the part it will produce. In this process, preprogrammed CNC equipment adjusts the arms and arbores to manufacture the spring, fine tuning elements including the spring’s free length, pitch, and coils. As the machines produce the spring, a high-speed camera takes pictures to track the process, allowing us to measure each part and make adjustments as necessary to ensure it stays within tolerance. From here, the machine cuts the spring from its wire, and the product travels into the stress relieving process.

Stress Relieving

The coiling process subjects the wire’s material to stress, causing it to become brittle. We correct this by heating the spring in an oven, allowing the coil to form metallic bonds and settle in its new shape. The oven holds the coiled wire at an appropriate temperature for a predetermined amount of time, and then slowly allows the coil to cool.

Finishing

Once the wire exits the stress relieving process, we then subject it to a number of finishing processes depending on its intended use. Spring finishing alters the spring from its original design to a specified tool that will benefit its future application. Some of the processes that go into spring finishing include:

- Grinding: We grind both ends of the spring to flat ends, allowing it to more easily attach to other surfaces

- Strength peening: This process helps steel resist metal fatigue and cracking despite high use and repeated flexing

- Setting: To permanently fix the spring’s desired length and pitch, we fully compress the spring so that all coils touch each other

- Coating: To prevent corrosion, we either paint the spring with non-corrosive paint, dip it in liquid rubber, or plate it with another metal such as zinc or chromium

- Packaging: We create custom packaging for springs, including bulk packaging in boxes or plastic bags

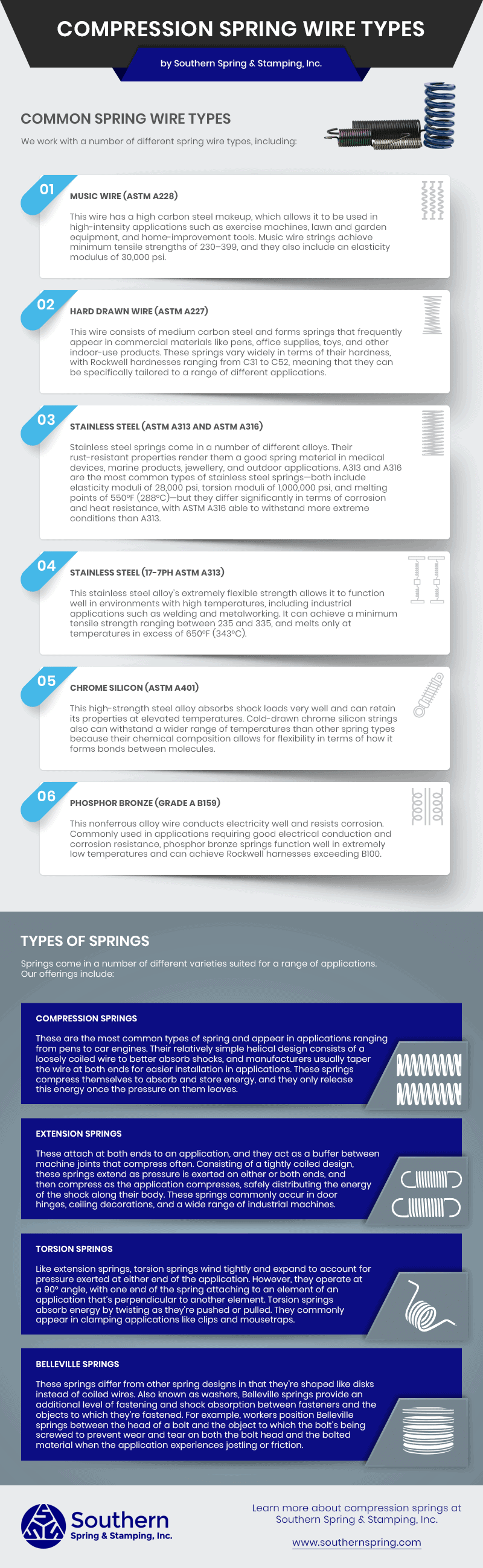

Common Spring Wire Types

We work with a number of different spring wire types, including:

Music wire (ASTM A228)

This wire has a high carbon steel makeup, which allows it to be used in high-intensity applications such as exercise machines, lawn and garden equipment, and home-improvement tools. Music wire strings achieve minimum tensile strengths of 230–399, and they also include an elasticity modulus of 30,000 psi.

Hard drawn wire (ASTM A227)

This wire consists of medium carbon steel and forms springs that frequently appear in commercial materials like pens, office supplies, toys, and other indoor-use products. These springs vary widely in terms of their hardness, with Rockwell hardnesses ranging from C31 to C52, meaning that they can be specifically tailored to a range of different applications.

Stainless steel (ASTM A313 and ASTM A316)

Stainless steel springs come in a number of different alloys. Their rust-resistant properties render them a good spring material in medical devices, marine products, jewelry, and outdoor applications. A313 and A316 are the most common types of stainless steel springs—both include elasticity moduli of 28,000 psi, torsion moduli of 1,000,000 psi, and melting points of 550°F (288°C)—but they differ significantly in terms of corrosion and heat resistance, with ASTM A316 able to withstand more extreme conditions than A313.

Stainless steel (17-7PH ASTM A313)

This stainless steel alloy’s extremely flexible strength allows it to function well in environments with high temperatures, including industrial applications such as welding and metalworking. It can achieve a minimum tensile strength ranging between 235 and 335, and melts only at temperatures in excess of 650°F (343°C).

Chrome silicon (ASTM A401)

This high-strength steel alloy absorbs shock loads very well and can retain its properties at elevated temperatures. Cold-drawn chrome silicon strings also can withstand a wider range of temperatures than other spring types because their chemical composition allows for flexibility in terms of how it forms bonds between molecules.

Phosphor bronze (Grade A B159)

This nonferrous alloy wire conducts electricity well and resists corrosion. Commonly used in applications requiring good electrical conduction and corrosion resistance, phosphor bronze springs function well in extremely low temperatures and can achieve Rockwell harnesses exceeding B100.

Types of Springs

Springs come in a number of different varieties suited for a range of applications. Our offerings include:

Compression springs

These are the most common types of spring and appear in applications ranging from pens to car engines. Their relatively simple helical design consists of a loosely coiled wire to better absorb shocks, and manufacturers usually taper the wire at both ends for easier installation in applications. These springs compress themselves to absorb and store energy, and they only release this energy once the pressure on them leaves.

Extension springs

These attach at both ends to an application, and they act as a buffer between machine joints that compress often. Consisting of a tightly coiled design, these springs extend as pressure is exerted on either or both ends, and then compress as the application compresses, safely distributing the energy of the shock along their body. These springs commonly occur in door hinges, ceiling decorations, and a wide range of industrial machines.

Torsion springs

Like extension springs, torsion springs wind tightly and expand to account for pressure exerted at either end of the application. However, they operate at a 90° angle, with one end of the spring attaching to an element of an application that’s perpendicular to another element. Torsion springs absorb energy by twisting as they’re pushed or pulled. They commonly appear in clamping applications like clips and mousetraps.

Belleville springs

These springs differ from other spring designs in that they’re shaped like disks instead of coiled wires. Also known as washers, Belleville springs provide an additional level of fastening and shock absorption between fasteners and the objects to which they’re fastened. For example, workers position Belleville springs between the head of a bolt and the object to which the bolt’s being screwed to prevent wear and tear on both the bolt head and the bolted material when the application experiences jostling or friction.

Hope Springs Eternal at Southern Spring and Stamping

Southern Spring and Stamping offers a full range of springs and other shock-absorbing applications for a variety of purposes, creating invaluable materials for both ballpoint pens and battleships. Learn more about our services at our official website and request a free quote if you like what you see.